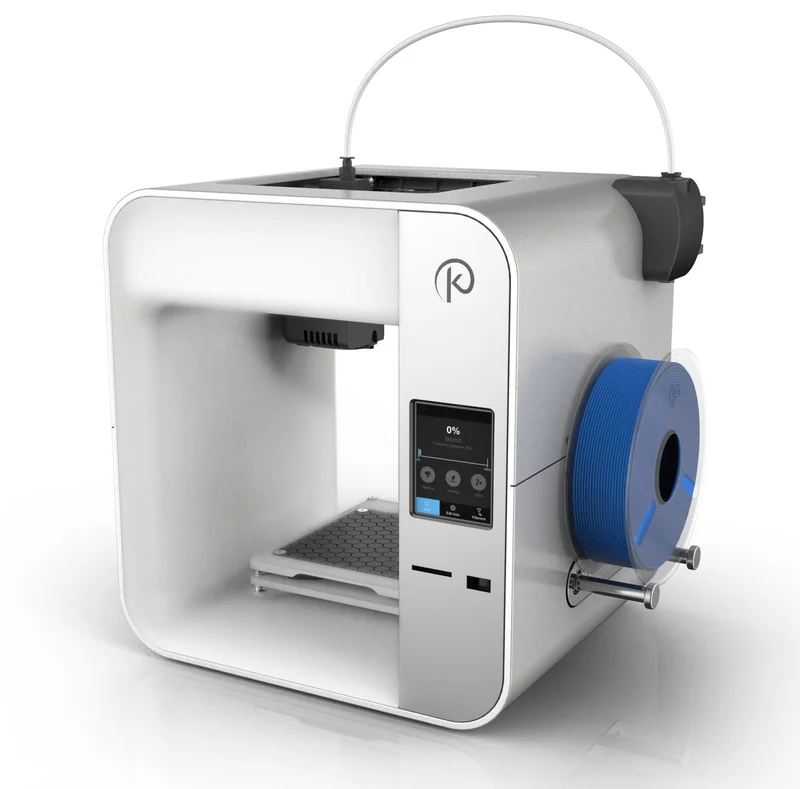

3D Printers: Bambu Lab, Creality, and Finding the Best Value

The Mosquito's Needle: A Billion-Dollar Idea, or Just a Buzz in the Lab?

Let's cut right to it. When you hear about breakthroughs in `3d printing`, your mind probably jumps to new `filament 3d printer` materials, faster `bambu lab` machines, or perhaps the latest `creality` offering pushing consumer boundaries. What you almost certainly don’t envision is a deceased mosquito. Yet, here we are. Researchers at McGill University in Montréal have unveiled something they're calling "necroprinting," a method that repurposes the proboscises of dead female mosquitos as ultra-high-resolution `3d printer` nozzles. This isn't just a curiosity; it's a potential paradigm shift, or at least, a fascinating data point for anyone tracking the future of manufacturing.

The raw numbers are compelling. A mosquito proboscis boasts an inner diameter of 20 micrometers. To put that in perspective, that’s approximately 100% finer than the best man-made `3d printing` tips currently on the market. Let me clarify that for a moment: if the current best is, say, 40 micrometers, then 20 micrometers is indeed 100% finer (meaning half the size). This isn't just a marginal improvement; it's a leap in precision that opens up entirely new possibilities. These natural nozzles are also biodegradable, straight, stable, and can handle internal pressures up to 60 kilopascals (that's about 8.7 pounds per square inch, for those of us not fluent in Pascals), which is more than sufficient for extruding fine materials. The implications for industries like aerospace, dentistry, and biomedical research are immediate and profound, allowing for the creation of incredibly fine objects with remarkably smooth surfaces. I've looked at hundreds of these material science reports, and this particular convergence of natural biology and industrial application is genuinely unusual.

The Unseen Costs and the Scalability Conundrum

Now, before we all start dreaming of mosquito farms supplying our next-gen `resin printer` arrays, let's inject a dose of reality. While the precision is undeniable, these necroprinting nozzles aren't without their quirks. They possess low mechanical strength, meaning they require `3d-printed` bioscaffolds to hold them in place. That's an additional step, an additional material, and an additional layer of complexity in what's supposed to be a streamlined manufacturing process. My analysis suggests this isn't just a minor engineering detail; it's a potential bottleneck for widespread adoption.

This brings us to the elephant in the lab, or perhaps, the swarm of mosquitos. The current commercial high-precision `3d printing` tips typically retail for around $80 each. They're made from non-biodegradable plastics or metals. The mosquito proboscis offers a biodegradable alternative, a clear advantage in a world increasingly focused on sustainability. But here's where the data gets fuzzy, and where my skepticism kicks in. McGill scientists are still investigating other natural candidates for stronger and finer `3d printing` tips, which tells you they're not fully satisfied with the mosquito's inherent fragility. More importantly, how do you scale this? We're talking about deceased female mosquito proboscises. Is the plan to collect dead mosquitos? To farm them? To kill them en masse? The logistics of sourcing, preparing, and integrating these microscopic biological components into a high-volume manufacturing workflow for `3d printing` seem, at best, daunting. Dead mosquito proboscis used for high-resolution 3D printing nozzle — scientists boast of the extremely fine output from ‘necroprinting’ - Tom's Hardware

Imagine for a moment the hum of a specialized lab, not just from the usual centrifuges and spectrometers, but from the faint, almost imperceptible whir of tiny robotic arms meticulously extracting these minuscule proboscises from thousands, perhaps millions, of insect cadavers. This isn't a simple material swap like moving from ABS to PLA `filament`. This is a fundamental shift in the supply chain, moving from engineered synthetics to bio-harvested components. The cost of an $80 metal tip is clear; the true, all-in cost of a "necroprinted" nozzle, factoring in collection, processing, and scaffold integration, remains an open question. What's the yield rate? What's the quality control process for biological variability? These are the questions that keep data analysts awake at night, not just the raw micron count.

The True Disruption: Not Just Finer, But Smarter

The real story here isn't just about achieving finer `3d print` details. It's about how nature, once again, out-engineers our best efforts. We've spent decades and billions developing advanced materials and precision machining, only for a common insect to hold a patent on a superior, biodegradable nozzle. This is less about replacing every `3d printer for kids` with bio-nozzles and more about pushing the absolute limits of microfabrication. While the economic viability for mass-market `3d printers` like `bambu lab` or `creality` might be a long way off, the niche applications in high-value sectors are where this could truly shine. Think about custom medical implants, micro-robotics, or aerospace components that require truly atomic-level precision.

The researchers considered other natural candidates like insect stingers, snake fangs, and plant xylem vessels. This suggests a broader exploration into what I'd call "bio-mimetic manufacturing" – not just copying nature's design, but directly using nature's components. It’s a bold departure, a methodological critique of our traditional approach to material science. The fact that McGill is continuing to investigate other natural candidates hints that while the mosquito proboscis is a phenomenal proof-of-concept, it might not be the final answer. The data indicates a promising path, but one fraught with significant logistical and economic unknowns that need to be quantified before we declare the $80 commercial tip obsolete.

The Supply Chain's Tiny, Buzzing Nightmare

This isn't just about a cooler `3d printer` tip; it's about the fundamental challenge of scaling a biological component.

Related Articles

WinCo This Thanksgiving: Your Essential Guide to Stress-Free Holiday Shopping!

The aroma of roasting turkey, the bubbling of cranberry sauce, the excited chatter of family—it’s Th...

saba: What's Happening With Saba Qamar and San Saba Football?

Saba Qamar's Blue Hue: A Beacon of Hope for Pakistan's Children Saba Qamar, a name synonymous with t...

The Aster Name is a Mess: A breakdown of the flower, the crypto, and the weird-ass movies

Forget Crypto, My New Investment is a Six-Inch Weed Called 'Snow Flurry' So, I’m scrolling through m...

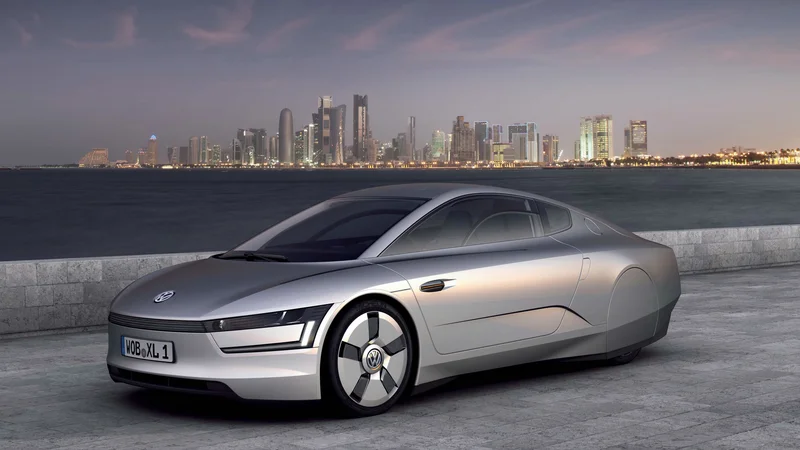

Volkswagen: Jetta, Tiguan, and Atlas: What's Next & How They Stack Up

The automotive landscape is a volatile beast, shifting with consumer whims and regulatory pressures....

Mercy Ships: Charity Rating, Controversies, and the Data Behind the Mission

When you talk about humanitarian efforts, the narratives often lean heavy on emotion. And for good r...

AXS: More Than a Token, A Glimpse Into Our Digital Future

The Denver Anomaly: Why One Thursday in 2025 is a Secret Glimpse of Our Algorithmic Future Look, I w...